Infrastructure

Production

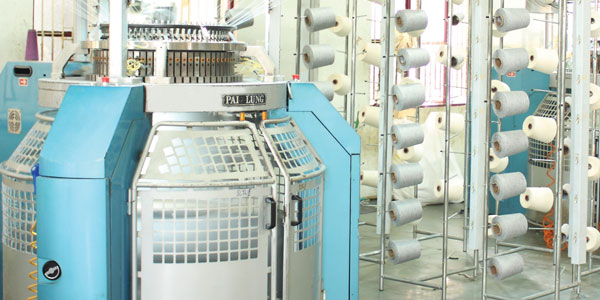

We have a contemporary design studio wherein the latest trends and techniques are deployed for garment design. The studio comes equipped with the most up-to-date software that facilitates pattern making, 3D imaging, graphics, draping, etc. Highly skilled work force combines with efficient and high technology machines to produce high quality products at all stages from cutting to sewing and to Finishing. Cutting is done manually and with help machines. For sewing the company uses 100 machines of make Juki, yamota and pegasus to produce 1500 to 2500 pcs per day depends upon the styles. Our monthly production capacity is upto 50,000 pcs.